Search

People also search for:

01 Overview

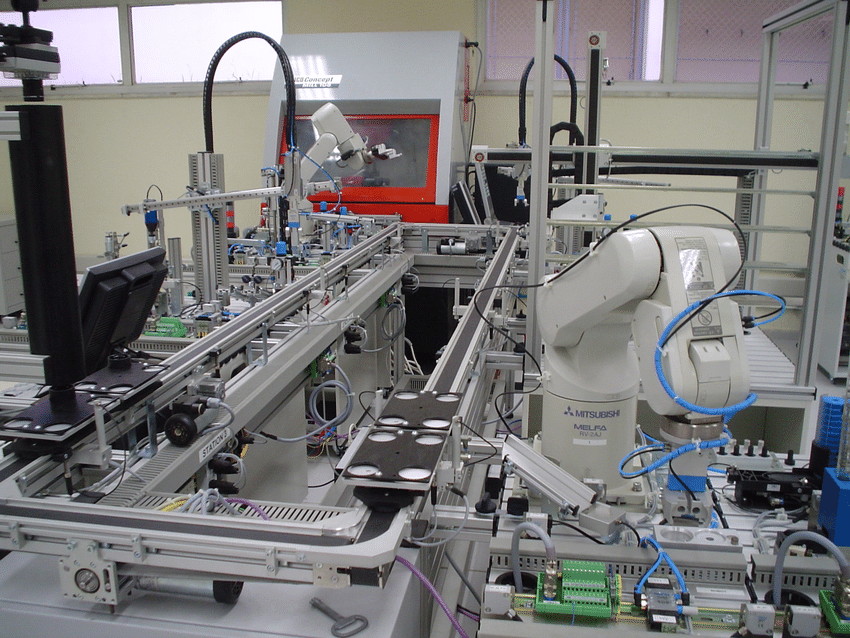

Manufacturing Solutions

Modern manufacturing environments require integrated, scalable, and smart extraction systems to keep production lines running clean, safe, and efficient. Our manufacturing solutions are designed to adapt to different workflows, materials, and contamination types — ensuring seamless operation, compliance, and cost-effective performance across industries.

02 Our Story

What we provide

03 Forgex Industrial Manufacturing Services

USED IN

01 Multi-process industrial production lines.

Multi-process industrial production lines.

Facilities with multiple machining, packaging, and assembly stations that need flexible vacuum infrastructure.

02 Clean assembly and inspection areas.

Clean assembly and inspection areas.

Precision zones requiring fume and dust control to maintain product quality and testing accuracy.

03 Textile, packaging, and paper-based operationsspan.

Textile, packaging, and paper-based operationsspan.

Plants where fiber dust, shredded waste, and static build-up can affect throughput and worker health.

04 Heavy-duty mechanical workshops.

Heavy-duty mechanical workshops.

Areas handling chips, greases, and liquids from grinding, polishing, or maintenance procedures.

05 Mixed-material production shops.

Mixed-material production shops.

Facilities working with metal, plastic, and wood — requiring modular extraction for diverse residues.

05 Flexible production or prototyping zones.

Flexible production or prototyping zones.

Agile environments where suction points and filtration needs change with each production batch.

04 Job Positions

Benefits

Flexible Integration Across Lines

Easily adapts to any production layout, with mobile or fixed extraction solutions

- Adapt To Workflow

- Scalable Design

- Flexible Setup

Continuous Waste Management

Removes waste at source to prevent downtime and reduce manual cleanup

- Smart Extraction

- No Clogs

- Continuous Flow

Cleaner Product Output

Ensures low-dust, contaminant-free production environments

- End To End Purity

- Clean Production

- Product Quality

Lower Maintenance & Downtime

Prevents buildup that damages machinery and interrupts production

- Maintenance Free

- Uptime Boost

- Dust Defense